Fuels From Our Yesterday's Trash!

Advanced Renewable

Wed , 13 Mar 2024 17:00 WIB

Like it or not, the fact is that the most widely used fuels in the world today are still fossil fuels, especially oil and gas. Unfortunately, oil and gas are not distributed evenly and supplies are limited. As a result, some countries become very rich because they have more than they need, while others are very dependent on supplies from these rich countries.

But this oil and gas was once - millions of years ago - also originally biomass, from plants, animals and microorganisms. Can we produce oil and gas like petroleum and natural gas, but from fresh biomass? biomass from our trash that we threw away yesterday?

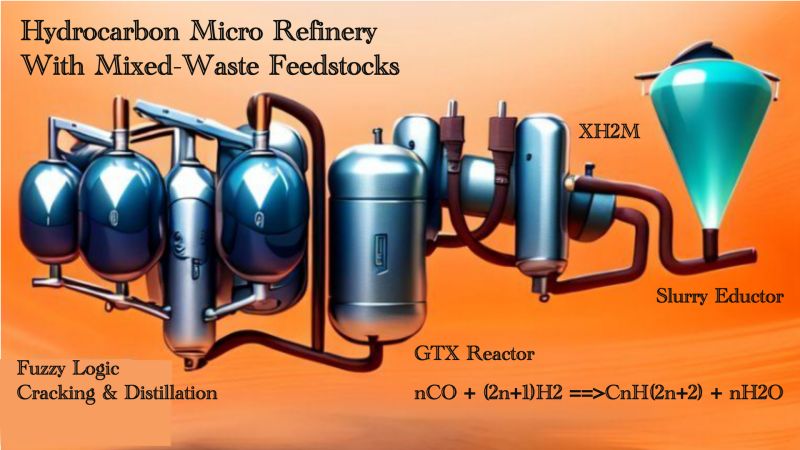

The answer is yes, we can! And in our laboratory, at the Advanced Renewable Organization (ARO), the entire process chain has been designed, the majority of parts have been tested. The appearance of the microplant is as in the picture below, this is for a capacity of around 750 liters of fuel per hour.

In essence, there are 4 stages of the process from wet or dry, organic or non-organic waste to become hydrocarbon fuel like the ones we use today, diesel, gasoline, jet-fuel or kerosene and LPG. The first stage is that the waste is milled into flour if it is dry or slurry if it is wet. These are the feedstocks that we put in the reservoir at the far right.

With a special technique called a slurry eductor, the flour or slurry is pressed by steam to enter the XH2M reactor chamber to be gasified, the output will be H2-Rich Syngas, namely syngas with an H2/CO ratio >2.

From here the syngas will be pressed again into the next reactor which we call GTX, Gas To X, X=D for diesel, X=G for gasoline, X=J for Jet-fuel, and X=L for LPG. These letters are not just the name for the desired product, but also relate to the required process parameters. Each letter represents at least 4 different parameters, namely operating temperature, residence time, pressure and the corresponding catalyst.

Even after controlling it with appropriate parameters, there is no guarantee that the output from XH2M is the fuel we want. It could be that the C chain is too long, or too short, etc. So we send the output from XH2M into another reactor which we call the Fuzzy Logic Reactor - apart from cracking, this reactor also sorts the final product so that it suits what we need.

With this Hydrocarbon Micro Refinery series, affordable and clean energy as mandated under SDGs target number 7 should be achieved throughout the world long before SDGs year 2030. Because the raw material is from rubbish and waste that we threw away yesterday, every community must have it!

Pos Lainnya

The Broken Cage

Mar 13, 2024

CCU Profit Centre

Mar 13, 2024

Green Waqf Framework Dissemination

Mar 13, 2024

Memperkenalkan Biofuel 5.0: Oksigenasi Regeneratif

Mar 13, 2024

Kategori

Renewable Energy

Silakan mendaftar terlebih dahulu!

Untuk memposting komentar baru. Anda harus login terlebih dahulu. Masuk

Komentar

Tidak ada komentar