Advanced Waste Palorization

Advanced Renewable

Wed , 06 Mar 2024 21:36 WIB

The waste crises continues to haunt our cities, at the same time the heavy burden of procuring energy, some of which still has to be massively imported - continues to be a significant factor in reducing our GDP, meaning it is still an impoverishing factor for those of us who continue to import this energy.

The solution to the first problem to overcome the second problem, waste into energy, has also been implemented, but it is still too small compared to the existing pile of waste, and has not had an impact on reducing fuel imports in the form of oil or gas. What caused it?

Garbage and biomass waste are actually very cheap sources of carbon, the carbon or C content in biomass ranges from 50% (original biomass) to 85% (biomass processed into charcoal). Meanwhile, it is from this C that all kinds of fuel and energy that we need can be produced.

However, when waste is only burned to become electricity, for example, the selling price of electricity which is only around US$ 0.1/kWh becomes a barrier. With the selling price of this final product, even 1 kg of waste that has become RDF (Refused-Derived Fuel) will at best only priced around 40% of the final product, or US$ 0.04/kg. At this level of selling price for RDF, processing waste into RDF is not yet a sustainable solution - because it definitely still has to be subsidized from other funding sources.

There is still a need for other solutions so that people are interested in processing their waste completely, and this can only be done if the business model is sustainable. For this, trash and waste must be directed as far as possible into products with the highest selling value. And in the energy sector, the highest selling price currently is hydrogen - above US$ 6/kg, next are hydrocarbon fuels such as gasoline and diesel - in the range of US$ 1.1/kg, and oxygenates fuels such as ethanol and methanol in the range of about US $0.5/kg.

From these comparative figures, if we can process our trash and waste into one of the fuels mentioned above, the waste processing business will be very promising. If it is economically attractive, piles of waste will automatically disappear from our cities.

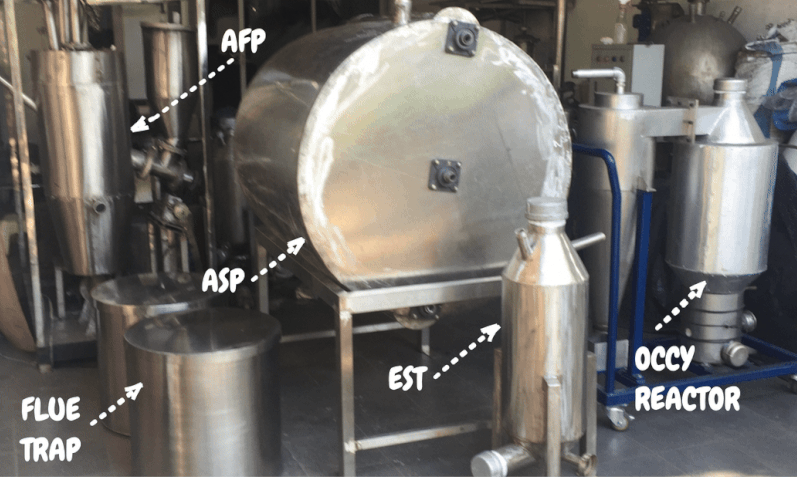

The machine below is one of our engineering works for processing any waste into hydrogen and syngas. Can be given feedstocks in the form of charcoal or native biomass. It takes 2.5 kg of charcoal to produce 1 kg of hydrogen, it takes 7.5 kg of dry biomass waste for the same 1 kg of hydrogen, whereas if it comes from wet waste, depending on the water content - it can be in the range of 15 - 25 kg of wet waste.

Whichever route is chosen, it is still very attractive because the current selling price for 1 kg of hydrogen is in the range of US$ 6 mentioned above. There is still enough room to make sophisticated machines, recruit the best talents and provide attractive returns for investors who want to invest in processing waste into hydrogen, hydrocarbon fuels and oxygenates.

Other Post

Integrated Carbon Capture for Fuel (ICCF)

Mar 06, 2024

Introducing XEtOH, An Advanced Bio-Ethanol

Mar 06, 2024

Appearance of Green Hydrogen Delivered by Charcoal

Mar 06, 2024

Energy Self-Sufficient in Anticipation of War

Mar 06, 2024

Karbonisasi Untuk Dekarbonisasi

Mar 06, 2024

Categories

Renewable Energy

Please register first!

For post a new comment. You need to login first. Login

Comments

No comments